In classical composites, two materials are combined at the microscopic scale to create a novel microarchitecture with properties better than the ones of its single components.

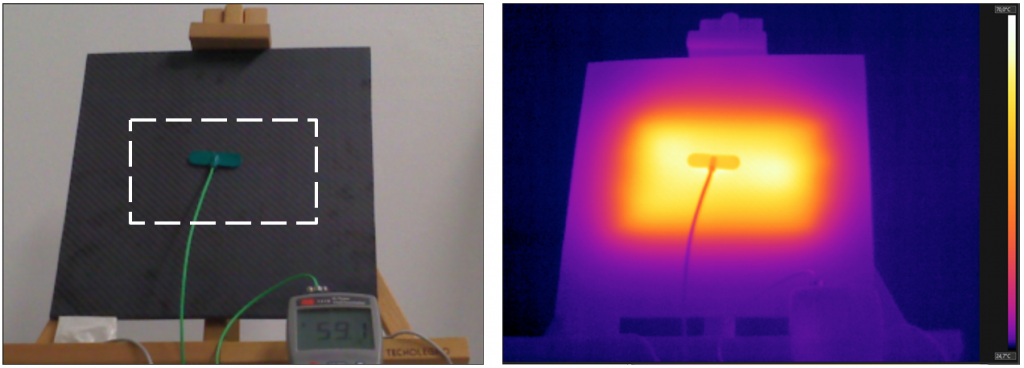

Classical composites such as example carbon-based reinforced polymers (CFRP), have revolutionised the field of engineering, automotive, aeronautics and Space, enabling novel structures with low weight and high mechanical performance. Nano-fillers provide improved mechanical properties to the composite materials, allow to reduce weight and reduce CO2 footprint or add new functionalities, like electrical conductivity, sensing or gas/water barriers to the material.

At ISOF, we combine different materials at the nanoscale to create hierarchical structures with improved properties or new functionalities (mechanical properties, electrical conductivity, magnetism, antimicrobic properties, light emission etc.). In particular, we create novel composites with a controlled structure at the micro-nanoscale, assembling together nanometric building blocks such as molecules, natural polymers, graphene, inorganic (hydrotalcite and metallic nanoparticles) and/or organic(polydopamine) to obtain films, nanofibers or sponges.

The composites we create are then tested in applications for the aeronautic, space and automotive fields, to reduce CO2 emissions by improving mechanical properties, reducing weight and adding new functionalities.